Fabric Carcass

Plylok and X Series

Fabric Carcass Families

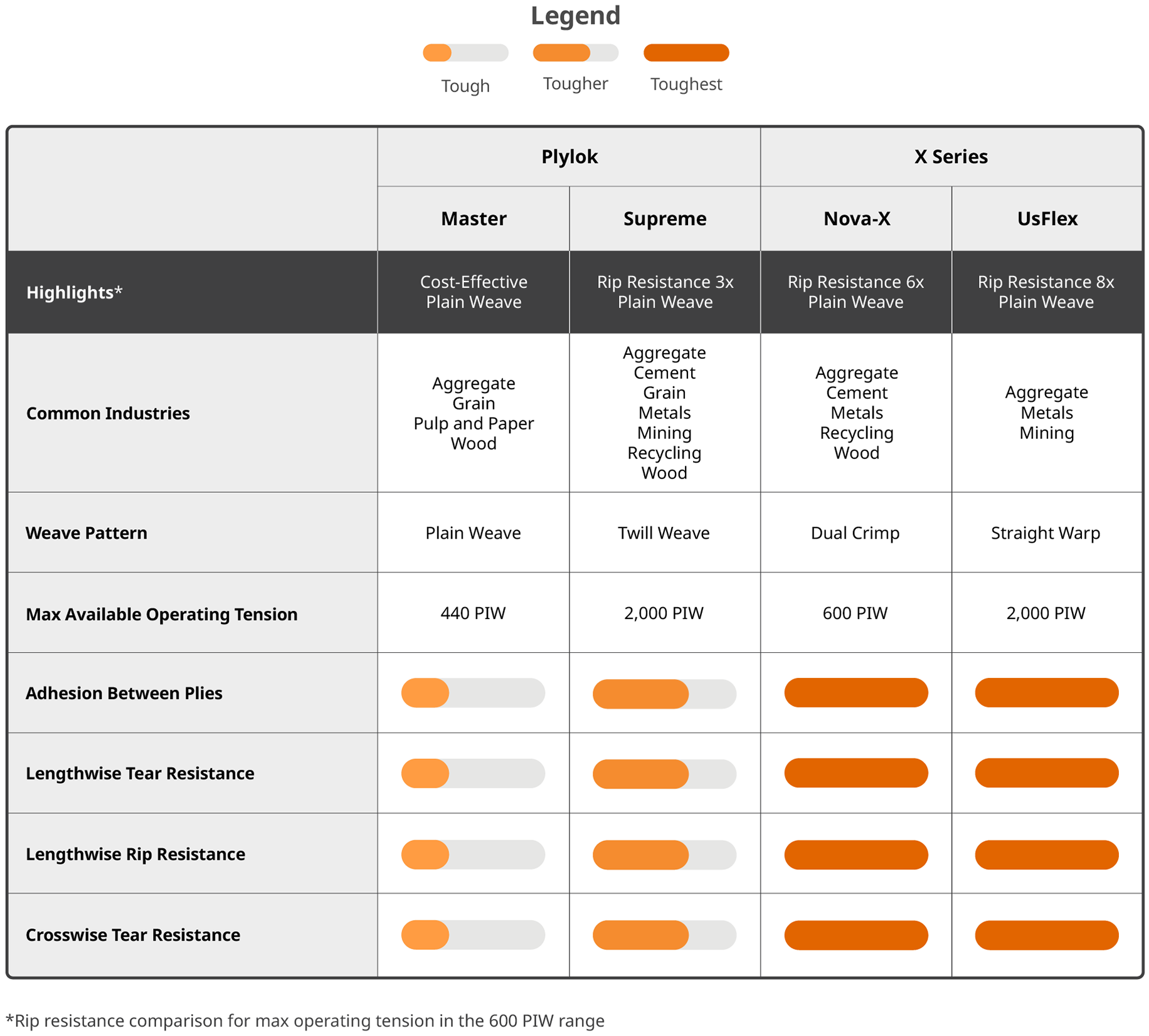

Fenner Dunlop’s Plylok and X Series are high-quality fabric carcass options, available across a wide range of operating tensions to suit diverse applications.

Plylok

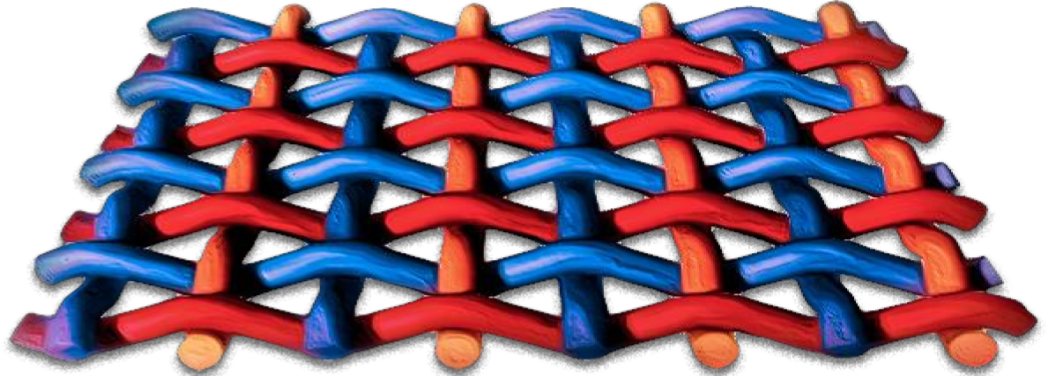

Plylok Master: A multi-ply plain weave pattern known for its durability and cost-effectiveness. Best suited for low to moderate tension applications.

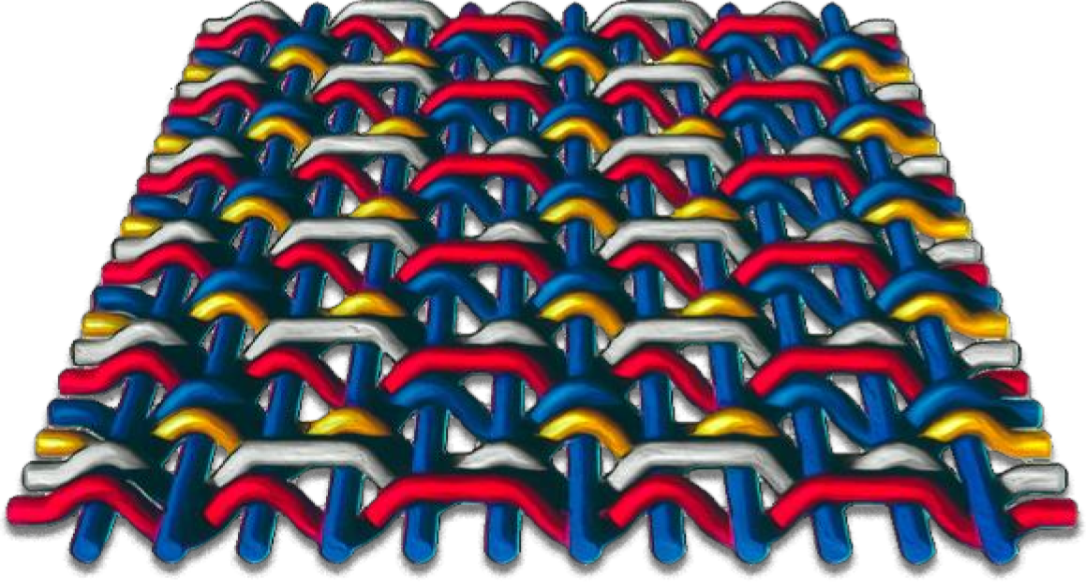

Plylok Supreme: Features a multi-ply twill weave pattern that provides superior resistance to impact, ripping, and tearing, along with enhanced adhesion compared to Plylok Master. Suitable for low to high tension applications.

3x Rip Resistance

X Series

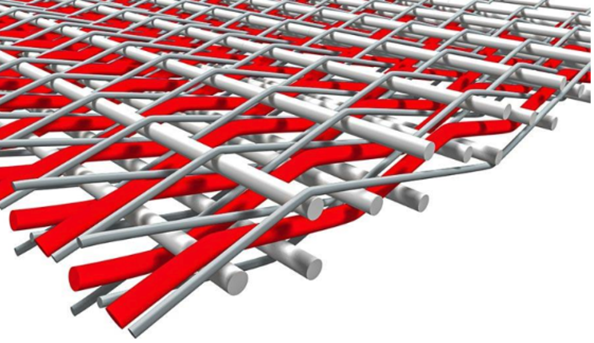

Nova-X: Utilizes a patented dual crimp pattern, offering exceptional impact, rip and tear resistance. It delivers superior adhesion and allows for smaller diameter pulleys thanks to its reduced gauge. The Nova-X’s design also improves throughability, tracking and load support, with unmatched fastener retention. Available in low to moderate tensions and a high-heat variant: Nova Xtreme.

6x Rip Resistance

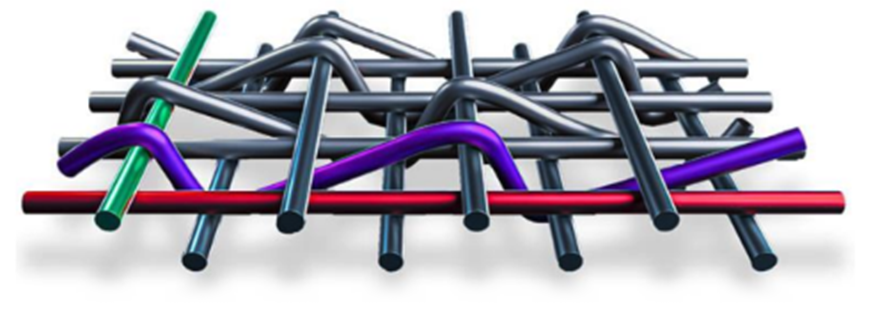

UsFlex: Built with a proprietary straight warp pattern, providing unparalleled impact, ripping and tearing resistance. The construction features straight yarns in parallel planes in the lengthwise and crosswise direction, locked together with a unique binder. This design reinforces the belt without weakening the yarn through crimping, and the binder acts as a built-in breaker for impact and puncture resistance. Available for low to high tension applications, and an aramid fiber variant for exceptional impact and puncture resistance: KordFlex.

8x Rip Resistance

Commonly Used Fabric Carcass Comparison

IMPORTANT FACT:

Fenner Dunlop is the Only Belt Company to Design and Produce Its Own Fabric

Fenner Dunlop stands out as the sole conveyor belt company that designs and produces its own fabric, ensuring unmatched performance and quality. This full control allows Fenner Dunlop to meticulously source and test only the finest raw materials, twist polyester and nylon yarns to strict specifications, and weave fabrics using proprietary designs for optimal results.

Fenner Dunlop’s complete oversight extends to the RFL treating process, where chemicals are carefully selected and heat-set to achieve superior adhesion and other critical physical properties. The behavior of polyester and nylon during RFL treatment is crucial, which is why precise material selection is important for optimal performance.

Unlike competitors who rely on third-party textile suppliers, Fenner Dunlop’s in-house production guarantees consistent, high-quality fabrics that outperform. Moreover, this comprehensive control has enabled the development of its unrivaled X Series proprietary carcass design, and over 100 specialized fabric carcass options tailored to meet the diverse demands of various applications and environments.