Covers

Fenner Dunlop continuously innovates rubber compounds to meet the highest standards across diverse applications

It offers over 50 cover options, categorized into two broad groups: General Purpose Covers and Specialty Covers, the most common of which are designed to resist the damaging effects of heat and oil.

General Purpose Covers

Key Properties of General Purpose Covers

Abrasion Resistance

The most critical factor for cover longevity, ensuring protection against wear from conveyed materials.

Cut and Gouge Resistance

Essential to prevent damage from impacts and sharp materials.

Adhesion

Strong adhesion between the cover and the plies is crucial to avoid premature delamination.

Cold Resistance

Especially important in regions like Canada, where low temperatures can weaken a covers’ resistance to cut, gouge, and abrasion, among other physical properties.

Ozone Resistance

Ozone exposure leads to cracking, which exposes the carcass, and reduces resistance to cut and gouge. All Fenner Dunlop covers are engineered to be ozone resistant, a feature too often overlooked by others.

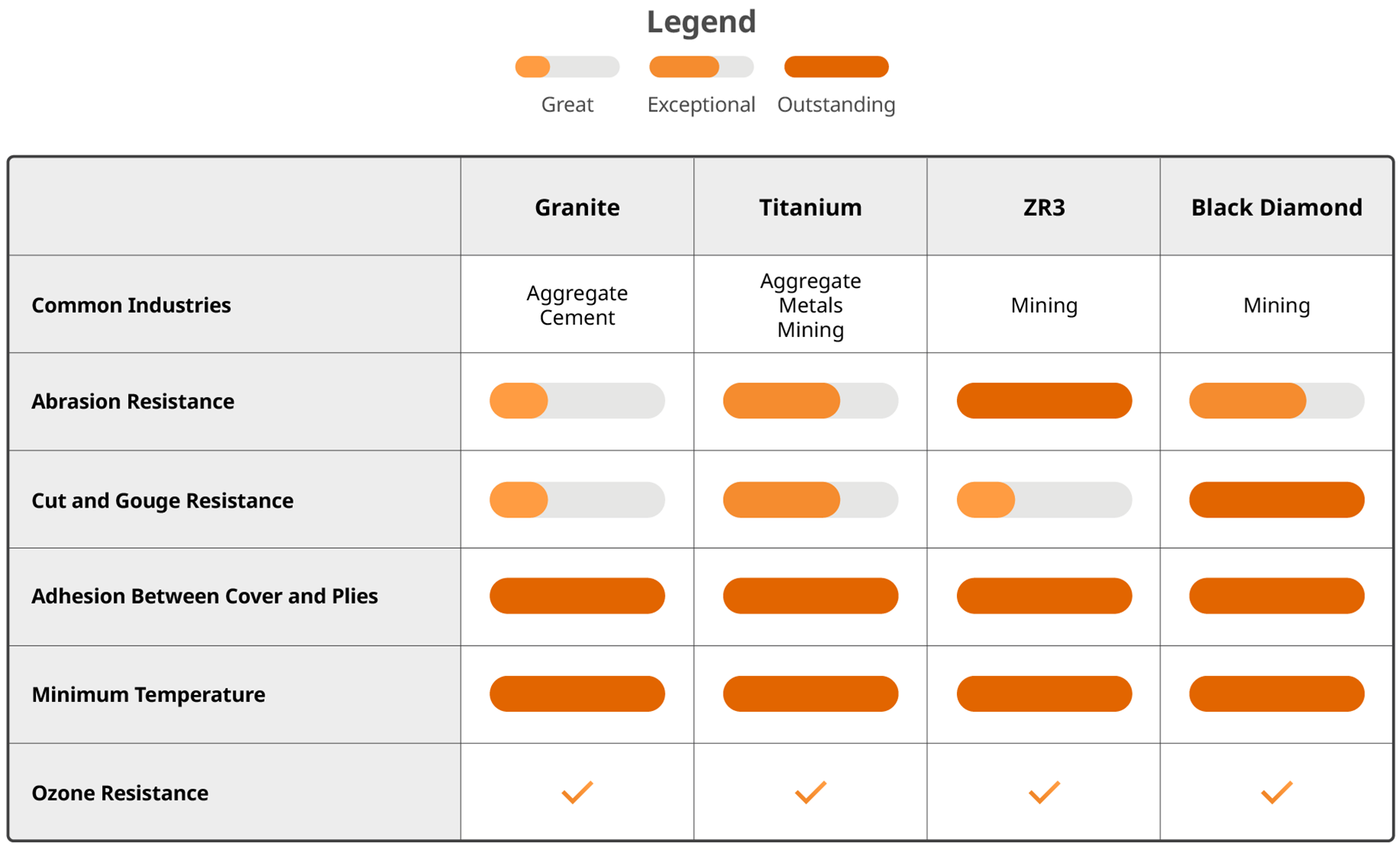

Commonly Used General Purpose Covers Comparison

- Granite: Cost-effective cover with superior abrasion resistance compared to ARPM Grade 1.

- Titanium: Balanced protection against cut, gouge, abrasion and cold; 2x the abrasion resistance of ARPM Grade 1.

- ZR3: Superior abrasion and extreme cold resistance; 6x the abrasion resistance of ARPM Grade 1.

- Black Diamond: Maximum resistance to cut and gouge; much higher abrasion resistance than ARPM Grade 1.

Heat Resistant Specialty Covers

Key Properties of Heat Resistant Specialty Covers

Heat Resistance

Heat can accelerate abrasion wear and weaken adhesion, causing premature delamination. Balancing heat resistance while retaining strong abrasion resistance and adhesion properties is essential for durability.

Abrasion Resistance

Still the most important factor, as heat-resistant covers must retain as much as possible of their protective qualities under high temperatures.

Adhesion

Critical to ensure the cover stays bonded to the carcass, preventing premature delamination in high heat applications.

Oil Resistance

In some cases, heat resistant covers must also be able to resist the damaging effects of oil that can cause swelling and distortion, leading to tracking problems.

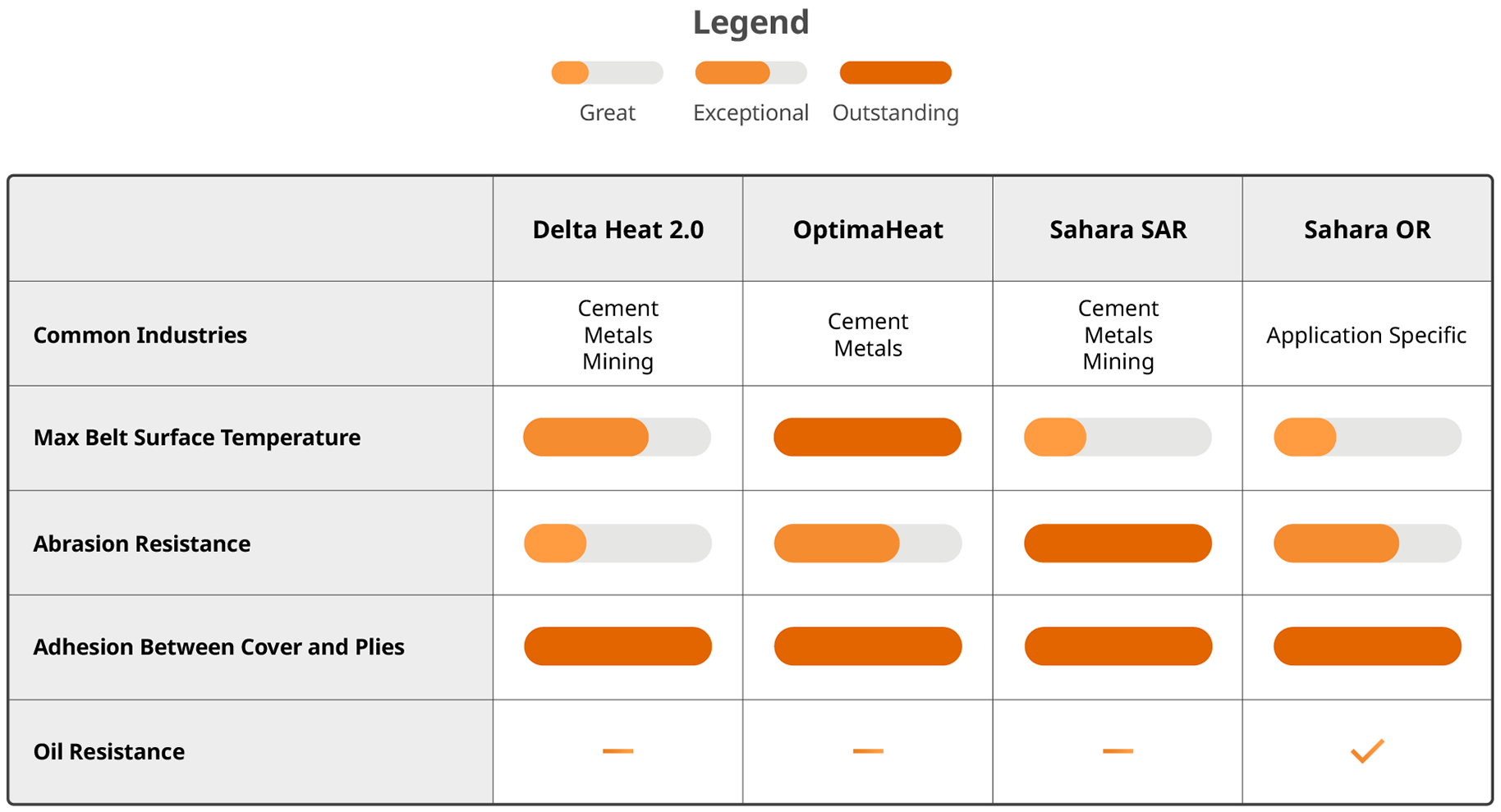

Commonly Used Heat Resistant Specialty Covers Comparison

- Delta Heat 2.0: Excellent resistance to very hot materials.

- OptimaHeat: Ultimate protection for extremely hot materials; better abrasion resistance compared to Delta Heat 2.0.

- Sahara SAR: Effective for moderately hot materials; 3x the abrasion resistance of Delta Heat 2.0.

- Sahara OR: Effective for moderately hot materials; excellent oil resistance for a compound that is also heat resistant.

Oil Resistant Specialty Covers

Nuera offers a broad range of specialty covers for oil applications, including:

- MOR: Engineered to resist moderate oily materials in both normal and cold conditions; commonly used in the wood, pulp and paper, and recycling industries.

- UGH 2.0: Versatile cover that meets the strict requirements of the grain industry. Exceeds OSHA standards for static conductivity, is flame retardant per MSHA Title 30 section 18.65 and ARPM-FR Class 2, and offers superior oil resistance under both normal and cold conditions.

Cover Profiles – CleatLine

Nuera offers a wide range of profiles to convey material at steep angles, among other special applications. Fenner Dunlop molds and vulcanizes these profiles into the base belt to form a single, homogenous belt structure.

Oil Resistant Specialty Covers

Nuera offers a broad range of specialty covers for oil applications, including:

- MOR: Engineered to resist moderate oily materials in both normal and cold conditions; commonly used in the wood, pulp and paper, and recycling industries.

- UGH 2.0: Versatile cover that meets the strict requirements of the grain industry. Exceeds OSHA standards for static conductivity, is flame retardant per MSHA Title 30 section 18.65 and ARPM-FR Class 2, and offers superior oil resistance under both normal and cold conditions.

Cover Profiles – CleatLine

Nuera provides a wide range of profiles to convey material at steep angles, among other special applications. Fenner Dunlop molds and vulcanizes these profiles into the base belt to form a single, homogenous belt structure.